SRG Plastic: Your Trusted Partner for Extrusion Molding Services and Injection Molding Services

In the world of manufacturing, precision, quality, and efficiency are crucial factors in delivering exceptional products. Whether you’re in the automotive, medical, packaging, or consumer goods industry, choosing the right molding service provider can significantly impact your product quality and production efficiency. SRG Plastic is a leading name in the industry, offering top-tier extrusion molding services and injection molding services to businesses worldwide.

Why Choose SRG Plastic for Your Molding Needs?

At SRG Plastic, we specialize in providing high-quality molding solutions tailored to meet the unique needs of various industries. Our commitment to innovation, technology, and customer satisfaction sets us apart as a trusted manufacturing partner.

- Expertise and Experience

With years of experience in the plastics industry, SRG Plastic has honed its expertise in both extrusion molding and injection molding. Our team of highly skilled engineers and technicians ensures precision, consistency, and superior quality in every project.

- Cutting-Edge Technology

We utilize state-of-the-art machinery and advanced automation to produce high-quality plastic components with minimal waste. Our investment in technology helps us maintain efficiency, reduce costs, and deliver exceptional results.

- Customization and Flexibility

At SRG Plastic, we understand that every business has unique requirements. We offer customized molding solutions that align with your specific design, material, and functionality needs.

- Competitive Pricing and Scalability

Our cost-effective solutions cater to both small-scale and large-scale production. Whether you need small-batch prototyping or mass production, we can scale our services accordingly without compromising on quality.

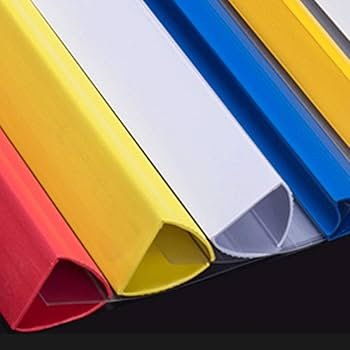

Extrusion Molding Services at SRG Plastic

What is Extrusion Molding?

Extrusion molding is a highly efficient plastic manufacturing process used to create continuous profiles such as pipes, tubing, sheets, and films. This process involves pushing melted plastic through a die to form a specific shape.

Advantages of Extrusion Molding

- Cost-Effective Production: Minimal material waste and lower tooling costs make extrusion molding an economical choice.

- High Production Efficiency: The continuous process allows for fast and consistent output.

- Versatile Applications: Suitable for a wide range of industries, including construction, automotive, packaging, and medical.

- Customization: Allows for the use of multiple materials and colors to achieve desired specifications.

Industries We Serve with Extrusion Molding Services

- Construction: Plastic pipes, siding, and window frames

- Medical: Tubing and protective films

- Packaging: Plastic film rolls and protective coverings

- Automotive: Wire coverings, trims, and seals

Our Extrusion Molding Capabilities

At SRG Plastic, we provide advanced extrusion molding services with a focus on precision and durability. Our capabilities include:

- Single and multi-layer extrusion

- Co-extrusion for multiple material applications

- Custom die design for unique profiles

- Material selection, including PVC, polyethylene, polypropylene, and more

Injection Molding Services at SRG Plastic

What is Injection Molding?

Injection molding is a widely used plastic manufacturing process that involves injecting molten plastic into a mold cavity, where it cools and solidifies into the desired shape. It is an ideal process for creating complex, high-precision plastic parts with tight tolerances.

Benefits of Injection Molding

- High Accuracy and Consistency: Ensures uniformity across all produced parts.

- Scalability: Suitable for high-volume production with low per-unit costs.

- Material Versatility: Works with various thermoplastics, including ABS, nylon, polycarbonate, and more.

- Efficient Production: Fast cycle times and repeatability reduce production time and costs.

Industries We Serve with Injection Molding Services

- Automotive: Dashboards, bumpers, and internal components

- Medical: Syringes, casings, and laboratory equipment

- Consumer Goods: Plastic housings, kitchenware, and household products

- Electronics: Enclosures, connectors, and keypads

Our Injection Molding Capabilities

SRG Plastic offers a wide range of injection molding services, including:

- Precision molding for intricate designs

- Overmolding for multi-material applications

- Insert molding for integrating metal and plastic parts

- Prototyping and low-volume production

- High-volume mass production

Why SRG Plastic is the Best Choice for Extrusion and Injection Molding Services

- Quality Assurance and Compliance

At SRG Plastic, quality is our top priority. We adhere to strict quality control standards and ISO-certified processes to ensure each product meets industry specifications. Our team conducts rigorous testing and inspections at every stage of production.

- Sustainable and Eco-Friendly Practices

We are committed to environmental responsibility and incorporate sustainable practices such as material recycling, energy-efficient manufacturing, and waste reduction.

- End-to-End Support

From concept to production, SRG Plastic provides comprehensive support to ensure seamless execution. Our team collaborates with clients to design, prototype, test, and manufacture high-quality plastic components.

- Global Reach and Reliable Supply Chain

We serve clients across various industries worldwide, ensuring on-time delivery and consistent quality with a well-established supply chain network.

Get Started with SRG Plastic Today

Whether you need custom extrusion molding services or high-precision injection molding services, SRG Plastic has the expertise, technology, and commitment to deliver exceptional results.