Maintenance Best Practices for Chain Conveyors

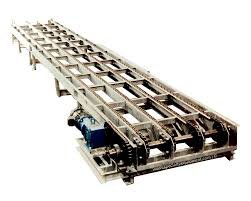

Perfection conveyor Chain conveyors are the workhorses of many industries, from manufacturing and packaging to logistics and agriculture. Their robust design and ability to handle heavy loads make them essential for efficient material handling. However, like any piece of machinery, chain conveyors require regular maintenance to ensure optimal performance, prevent costly downtime, and prolong their lifespan. This blog post outlines essential maintenance best practices for your chain conveyor system.

1. Regular Inspection: The Key to Prevention

Proactive maintenance starts with regular inspections. Establish a routine inspection schedule, ideally daily or weekly, depending on the intensity of usage. During these inspections, focus on the following:

- Chain Wear and Tension: Check the chain for signs of wear, such as elongation, corrosion, or damaged links. Ensure proper chain tension; excessive slack can cause slippage and jerky movements, while over-tightening can lead to premature wear and increased stress on the motor. A well-maintained chain conveyor has consistent chain tension.

- Sprocket Condition: Inspect sprockets for wear, broken teeth, or misalignment. Worn sprockets can damage the chain and reduce efficiency.

- Lubrication: Proper lubrication is crucial for minimizing friction and wear. Follow the manufacturer’s recommendations for the type and frequency of lubrication. Ensure all moving parts, including chains, sprockets, and bearings, are adequately lubricated. A properly lubricated chain conveyor operates smoothly and efficiently.

- Guards and Safety Devices: Verify that all safety guards and devices are in place and functioning correctly. This is essential for protecting personnel and preventing accidents.

- Cleanliness: Keep the chain conveyor and surrounding area clean and free from debris. Accumulated dirt and grime can accelerate wear and interfere with proper operation.

2. Lubrication: The Lifeblood of Your Chain Conveyor

Lubrication is arguably the most critical aspect of chain conveyor maintenance. Choose a lubricant specifically designed for chain conveyors, considering factors such as operating temperature, load, and environmental conditions.

- Type of Lubricant: Select the appropriate lubricant based on the application. Options include oil, grease, and dry lubricants.

- Application Method: Use proper lubrication techniques, such as drip lubrication, oil bath, or automatic lubrication systems.

- Frequency: Follow the manufacturer’s recommendations for lubrication frequency. More frequent lubrication may be necessary in harsh environments or under heavy loads.

3. Tension Adjustment: Finding the Right Balance

Maintaining proper chain tension is essential for smooth operation and preventing premature wear.

- Check Regularly: Regularly check chain tension and adjust as needed.

- Follow Guidelines: Adhere to the manufacturer’s guidelines for tension adjustment.

- Avoid Over-Tightening: Over-tightening can put excessive stress on the chain, sprockets, and motor.

4. Component Replacement: Knowing When to Act

Even with diligent maintenance, components will eventually wear out and need replacement.

- Regular Inspections: Regular inspections will help identify worn components before they cause major problems.

- Replace Worn Parts Promptly: Replace worn chains, sprockets, and bearings promptly to prevent further damage and downtime.

- Use Quality Parts: Use high-quality replacement parts that meet or exceed the original equipment specifications.

5. Training and Documentation: Empowering Your Team

Proper training and documentation are essential for effective maintenance.

- Train Personnel: Train maintenance personnel on proper inspection, lubrication, and adjustment procedures.

- Maintain Records: Keep detailed maintenance records, including inspection dates, lubrication schedules, and component replacements.

By implementing these maintenance best practices, you can maximize the lifespan and efficiency of your chain conveyor system, minimize downtime, and ensure a safe and productive work environment.

Perfection conveyor is India’s leading manufacturer of Chain Conveyor . You can contact them for further information regarding the Chain Conveyor at